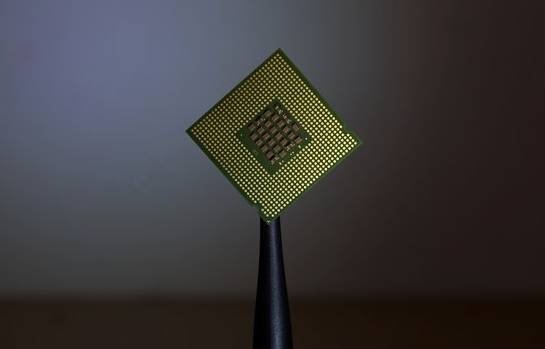

Why are microchip wafers round? Why do they waste time drawing unfinished chips around the edges? Microchip wafers are typically round for several practical reasons that relate to both manufacturing processes and efficiency in utilizing the wafer material.

Manufacturing Process:

The process of creating microchips involves several intricate steps, such as photolithography, etching, deposition, and more. These processes are often carried out using machines that rotate the wafer to ensure uniformity in the manufacturing process. A round wafer can be rotated more smoothly and consistently, which helps in achieving uniform results across the entire wafer’s surface.

Materials and Efficiency:

Semiconductor wafers are made from silicon, which is commonly available in round ingots or boules. The round shape allows for efficient use of the silicon material, minimizing wastage during the cutting and shaping process. Round wafers are also easier to handle and transport within the manufacturing facility.

Consistency:

The circular shape of wafers helps ensure consistent and predictable processing. The manufacturing equipment is designed to accommodate round wafers, allowing for precise control of processes like doping, deposition, and etching.

Regarding your mention of “etching incomplete chips around the edges,” it’s important to clarify that modern semiconductor manufacturing techniques have significantly reduced the occurrence of incomplete chips on the edges of wafers. The yield and efficiency of chip manufacturing have improved over the years, minimizing the wastage of valuable materials.

However, some degree of edge wastage might still occur due to variations in the manufacturing process or defects that can develop during various steps. Manufacturers often have strategies to mitigate these issues, such as using a portion of the wafer’s edge for test structures or redundant features. Additionally, as technology advances, there’s a constant push to maximize the usable area of each wafer, reduce defects, and improve yield.

In summary, the round shape of microchip wafers is a result of various considerations related to manufacturing processes, material utilization, and consistency. While edge wastage and incomplete chips have been challenges in the past, advancements in manufacturing techniques have significantly improved yield and efficiency, making these issues less prevalent in modern semiconductor fabrication.